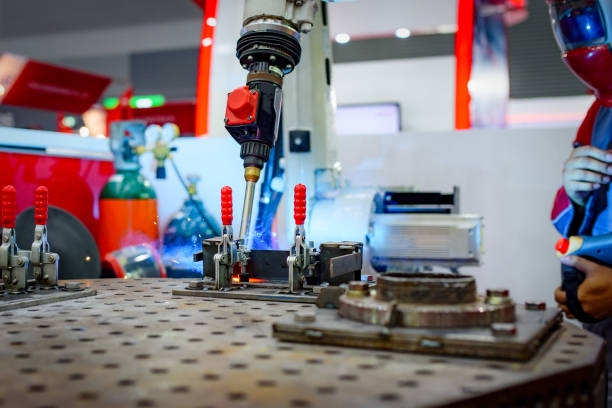

The influence of End of Arm Tooling (EOAT) on product quality in automation and robotic systems is profound. EOAT directly affects the accuracy, consistency, and overall quality of the manufacturing process.

- Precision and Accuracy: Advanced EOAT offers unparalleled precision, crucial in tasks requiring high accuracy. This directly translates to improved product quality, reducing errors and inconsistencies.

- Gentle Handling for Quality Assurance: For delicate products, the gentle handling capabilities of modern EOAT ensure that products remain undamaged, maintaining quality standards.

- Adaptability to Various Materials: The ability of EOAT to adapt to different materials and shapes without compromising the integrity of the product is vital for maintaining quality across diverse production lines.

- Reduction in Human Error: Automated systems with high-quality EOAT reduce the likelihood of human error, which can significantly impact product quality.

- Consistency Over Time: EOAT maintains consistent performance over long periods, ensuring that the quality of the products remains uniform.