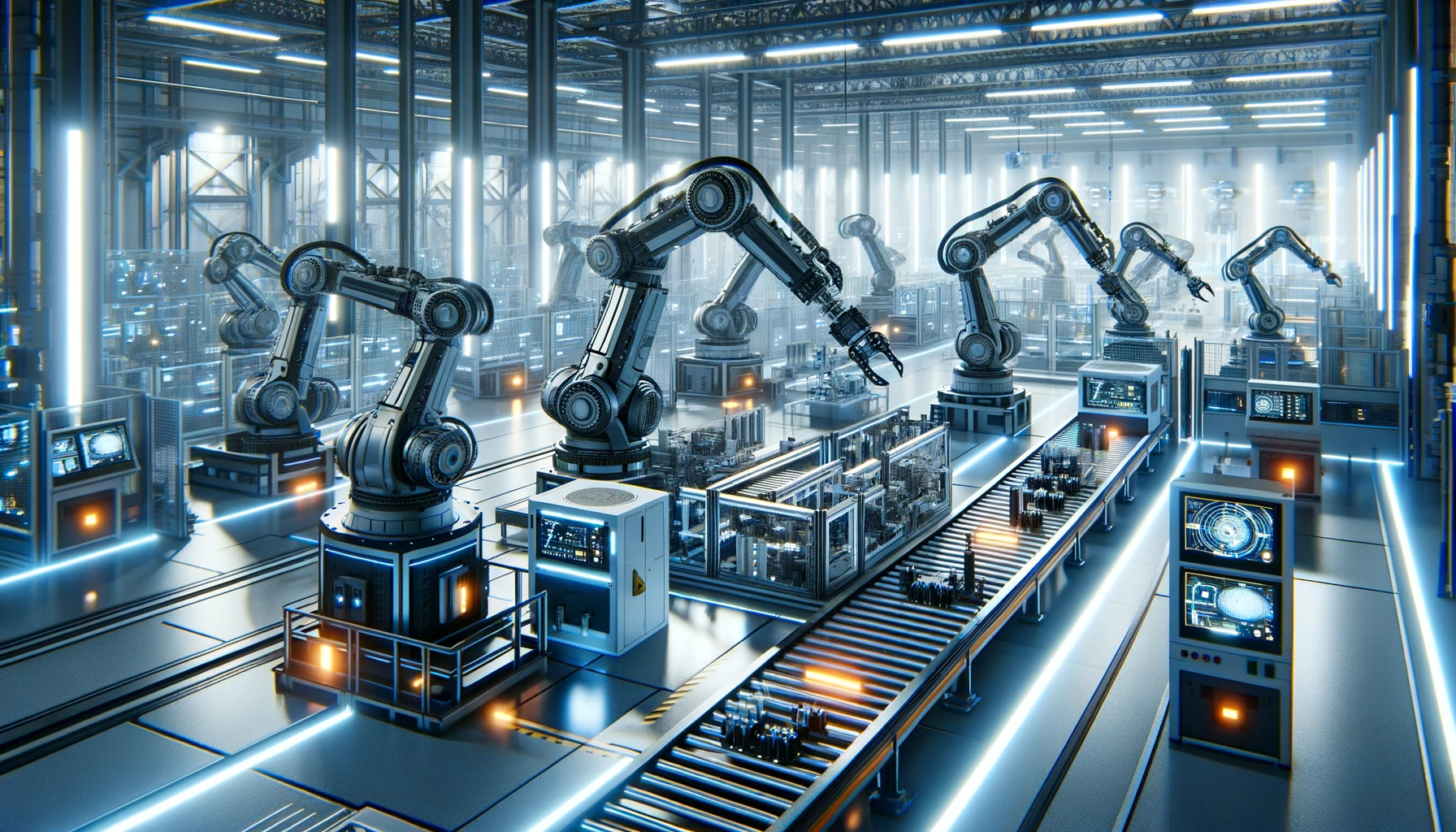

When it comes to automation and robotics, selecting the right End of Arm Tooling (EOAT) is crucial for operational success. This involves a careful assessment of the specific requirements of each application.

- Understanding the Application Needs: Start by analyzing the task at hand. Consider factors like the weight of the objects to be handled, the required precision, and the environmental conditions. This will help narrow down the type of EOAT needed, whether it’s for gripping, welding, or assembly.

- Material Considerations: The materials being handled by the EOAT play a significant role in tool selection. For example, handling delicate or soft materials may require soft grippers, while magnetic or vacuum grippers might be better suited for metal or smooth-surfaced items.

- Speed and Efficiency: Evaluate the speed requirements of your process. Some tools are designed for high-speed operations, while others prioritize precision over speed.

- Compatibility with Robots: Ensure that the EOAT is compatible with your existing robotic systems in terms of size, weight, and interface. This compatibility is crucial for seamless integration and operation.